A group of students at Pitt Meadows Secondary have combined a love of angling with their skills in the woodshop.

With pieces of quarter-sawn white oak, water, heat, and lots of trial and error, teacher Matthew Mikes and his students have created their own custom fishing nets.

“It has been really great,” he said. “The students have gone through the whole process.”

Mikes was gifted a fishing net from a local maker and decided he and his students would try to recreate the final product. After some experimentation, they settled on a process that has been producing some impressive results.

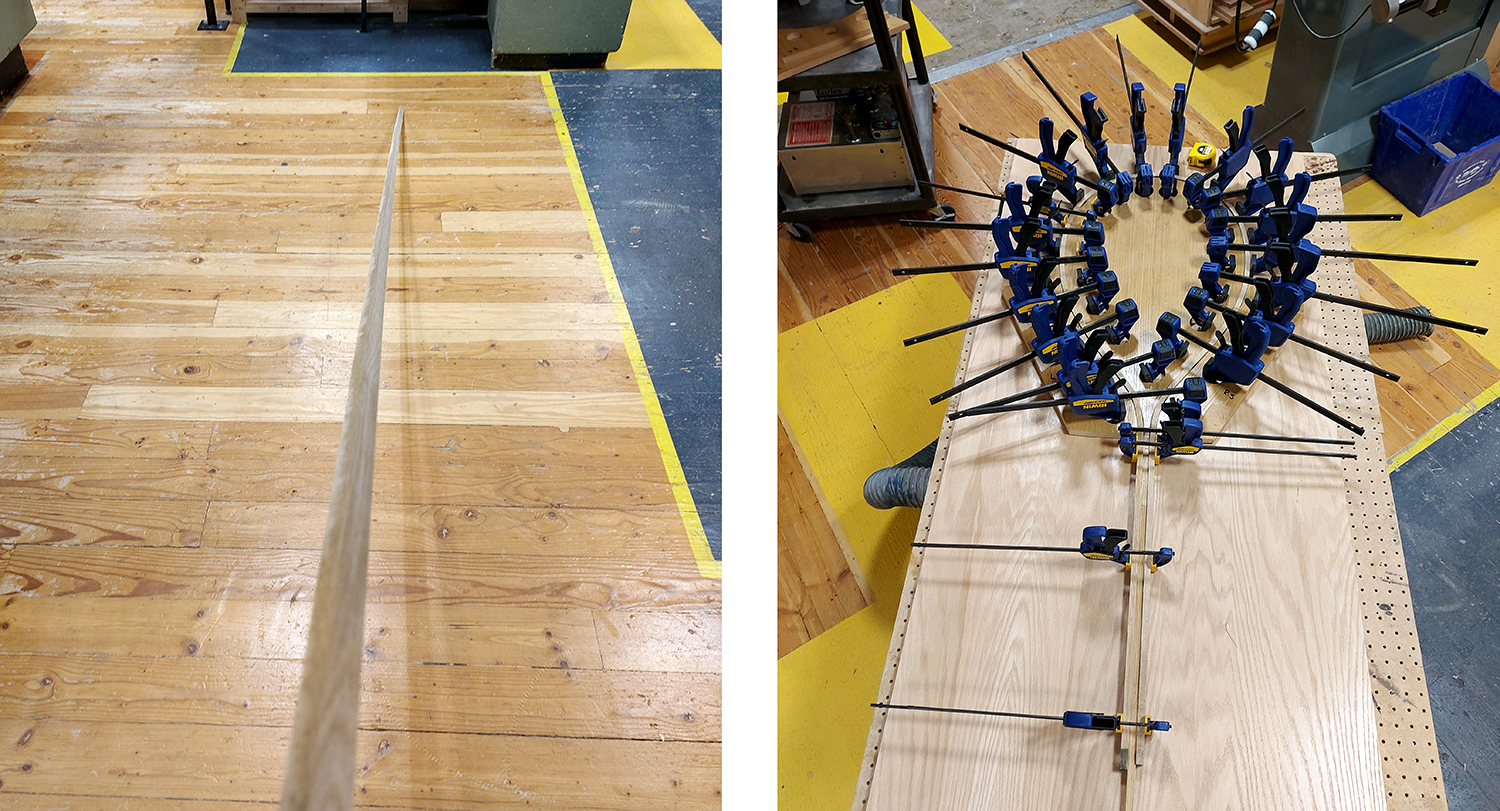

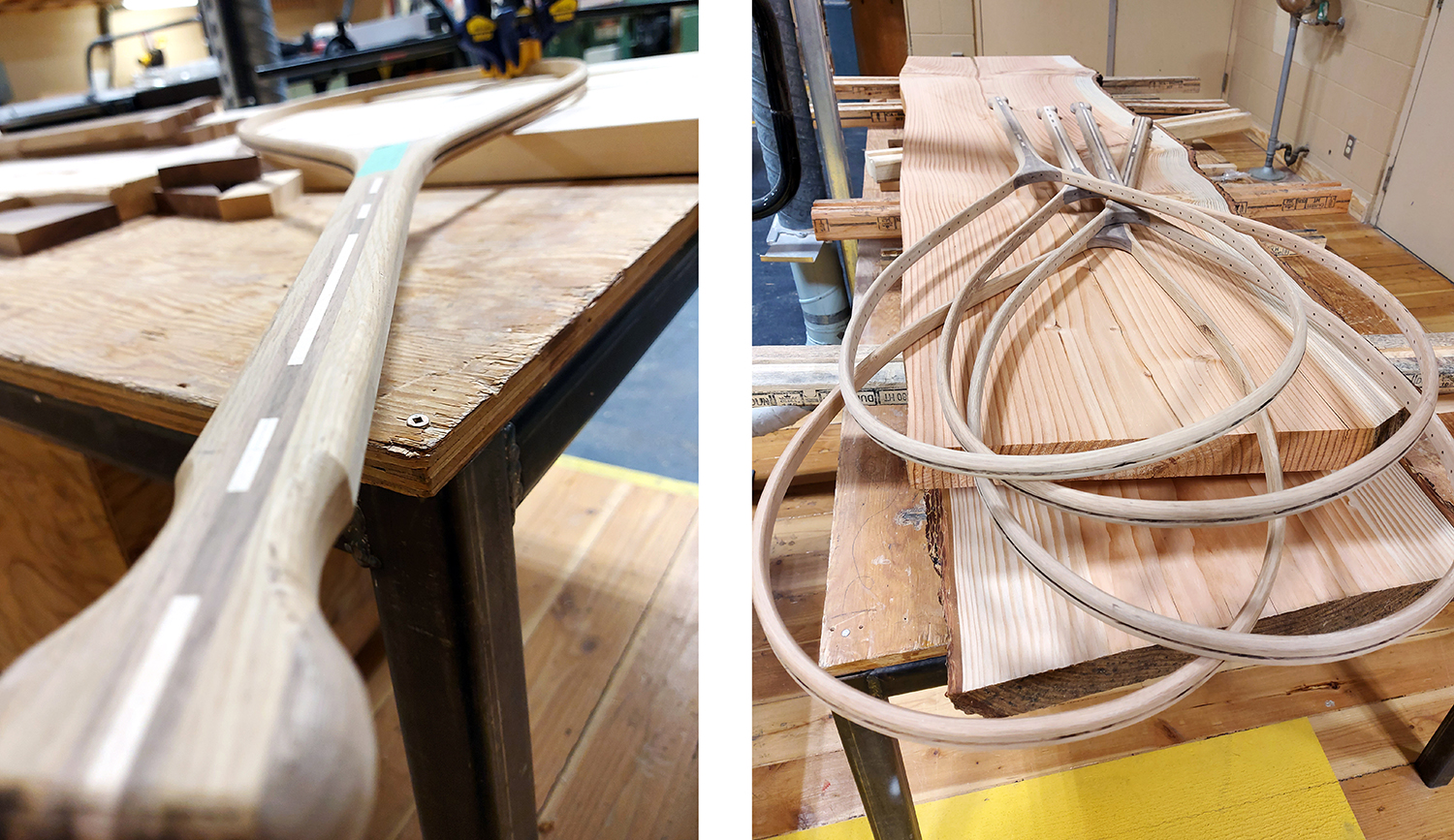

First, a ten-foot-long cut of wood is soaked overnight in a piece of PVC piping filled with water. In the morning, the oak is placed in a steam box for several hours until it is bendable enough that it can be shaped. Students must then act quickly to get the wood into a form and clamp it into place before it cools and hardens. The piece then stays in the form until it is completely dry.

“We did a lot of research and experimenting,” Mikes said. “With just the moisture, it is not bendable enough. You add the heat, and it changes the molecular structure.”

After the oak is shaped, an inlay is glued into the handle, varnish is applied, and the netting is threaded through holes in the wood.

Most of the students that have participated in the net-making project are members of the Pitt Meadows Secondary fishing club, which is also run by Mikes.

He said it has been fun to watch the students research the best process and troubleshoot issues with the design.

“I’m really proud of them,” Mikes said. “We all learned it together and I think it was great they were able to experience this.”